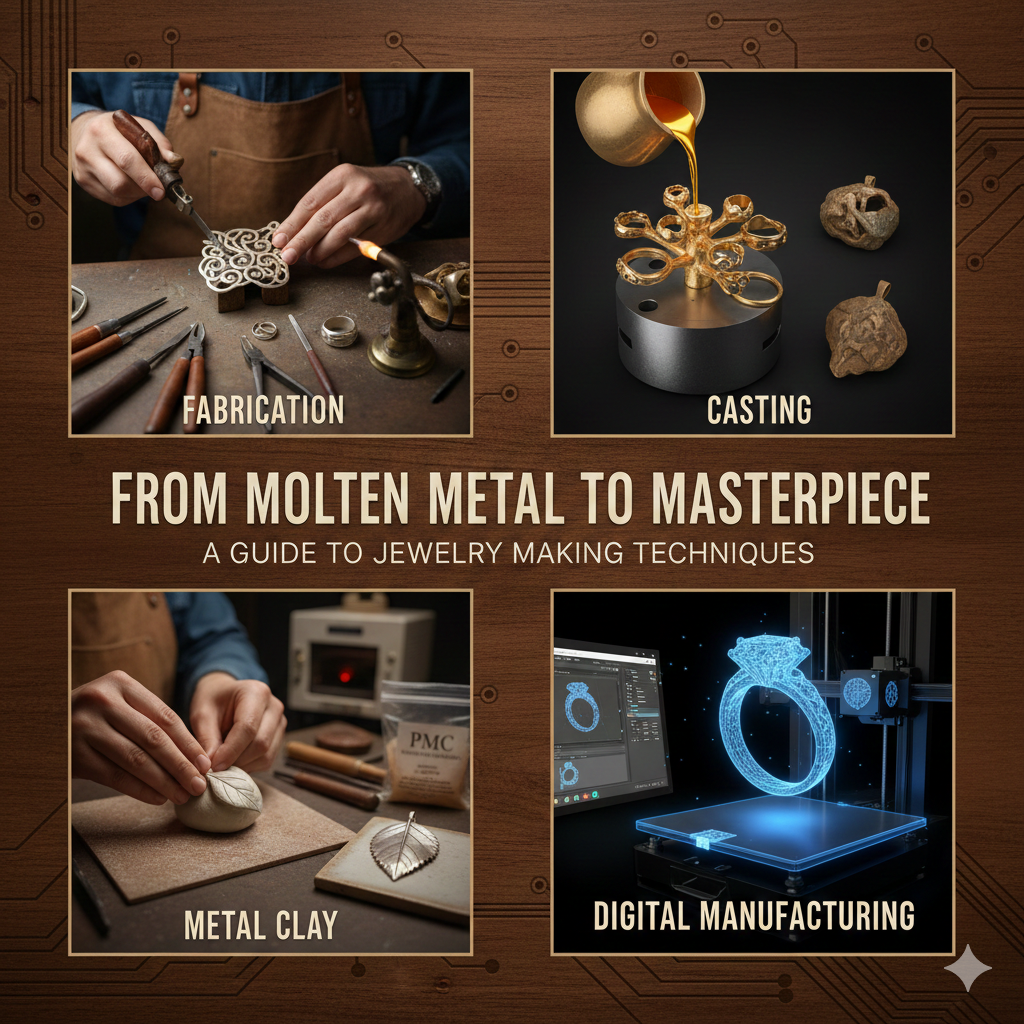

From Molten Metal to Masterpiece: A Very “Small Guide” to Jewelry Making Techniques

Whether it is a simple silver band or an intricate gold necklace encrusted with gems, every piece of jewelry tells a story of creation. For aspiring jewelers and curious collectors alike, understanding how a piece is made creates a deeper appreciation for the craft.

Jewelry making is a unique blend of chemistry, engineering, and art. Below, we explore the four primary pillars of jewelry creation: Fabrication, Casting, Metal Clay, and Modern Digital Manufacturing.

1. Fabrication: The Art of Construction

Fabrication is the oldest and most traditional method of making jewelry. Think of it as “construction work” on a miniature scale. Instead of melting metal into a mold, the jeweler builds the piece from raw materials like sheet metal and wire.

- Sawing and Piercing: Using a jeweler’s saw with a blade finer than a hair, the artist cuts intricate shapes out of gold or silver sheet metal. This is the foundation of most handmade pendants and charms.

- Soldering: This is the “glue” of metalsmithing. Using a torch and a metal alloy (solder) that melts at a slightly lower temperature than the workpiece, the jeweler permanently joins separate components—like attaching a bezel cup to a ring shank.

- Forging: Using hammers and an anvil, the metal is beaten to shape, stretch, or texture it. Forging compresses the metal’s grain structure, making it harder and stronger (a process called work-hardening).

- Cold Connections: Not all joining requires heat. Riveting, tab-setting, and wire-wrapping allow jewelers to connect mixed metals or delicate materials (like wood or pearls) that might be damaged by a torch.

Best For: One-of-a-kind bespoke pieces, clean geometric lines, and durable everyday wear.

2. Casting: The Magic of Molten Metal

Casting is the technique of pouring liquid metal into a mold. It allows for complex, organic 3D shapes that would be impossible to fabricate by hand.

- Lost-Wax Casting (Investment Casting): The industry standard for fine jewelry.

- The artist carves a model out of wax.

- The wax is encased in a plaster-like material called “investment.”

- The flask is heated in a kiln; the wax melts and burns away (is “lost”), leaving a negative cavity.

- Molten gold or silver is poured (or centrifuged) into the void.

- Sand Casting: A more primitive and rustic method where a rigid object is pressed into specialized oily sand to create a mold. Molten metal is poured directly into the sand. It creates a distinctively textured, “imperfect” surface that is popular in contemporary artisanal jewelry.

Best For: Organic shapes, high-detail texture, and reproducing the same design multiple times (production runs).

3. Metal Clay: Alchemy for Beginners

Emerging in the 1990s from Japan, metal clay revolutionized jewelry making by lowering the barrier to entry.

- The Process: Metal clay consists of microscopic particles of precious metal (silver, gold, bronze, or copper) mixed with an organic binder and water. It feels and acts like modeling clay. You can shape it, roll it, mold it, and texture it by hand.

- Firing: Once dry, the piece is fired in a kiln or with a handheld torch. The binder burns away, and the metal particles sinter (fuse together), resulting in a piece of solid metal jewelry (usually 99.9% pure silver or high-karat gold).

Best For: Beginners, sculptors, and artists who want to create metal jewelry without learning complex sawing or soldering techniques.

4. Digital Manufacturing: The Future is Now

Modern technology has not replaced the jeweler; it has given them new tools. The “CAD/CAM” revolution allows for precision that the human hand sometimes cannot achieve.

- CAD (Computer-Aided Design): Designers use software like Rhino or Matrix to build a piece of jewelry in a 3D virtual environment. This allows for precise weight calculations and perfect symmetry.

- 3D Printing: Once the CAD file is ready, a 3D printer creates a high-resolution wax or resin model. This model is then used in the Lost-Wax Casting process described above.

- Laser Sintering: In high-end industrial manufacturing, lasers can fuse metal powder layer-by-layer to build a piece of jewelry directly, skipping the casting stage entirely.

Best For: Complex engagement rings with many stone settings, mass production, and designs with impossible geometries (like hollow latticework).

5. Decorative Finishes: The Final Touch

Once the metal is shaped, the character is added through finishing techniques.

- Enameling: Fusing powdered glass to the metal surface in a kiln, adding vibrant color. Techniques include Cloisonné (using wires to create cells for color) and Plique-à-jour (stained-glass effect).

- Mokume Gane: An ancient Japanese technique where layers of different colored metals (like gold, silver, and copper) are fused, twisted, and flattened to create wood-grain patterns.

- Patinas: Using chemical solutions to oxidize the metal, turning silver black or bronze green/blue to highlight textures and add an antique look.

Conclusion

Whether hammered on an anvil or printed from a digital file, the goal of jewelry making remains the same: to create a wearable object of beauty. The “best” technique depends entirely on the vision of the artist.